Kingyou has the capability of manufacturing precision moulds, metal processing, automatic production of injection parts, and integrated production of coustic products. Through a large number of production practices and process development, we have formed a set of lean production technology and standardized operation process of electroacoustic products. In terms of production efficiency, product pass through rate, production qualification rate, product consistency and stability, we strive for perfection and form outstanding lean production capacity.

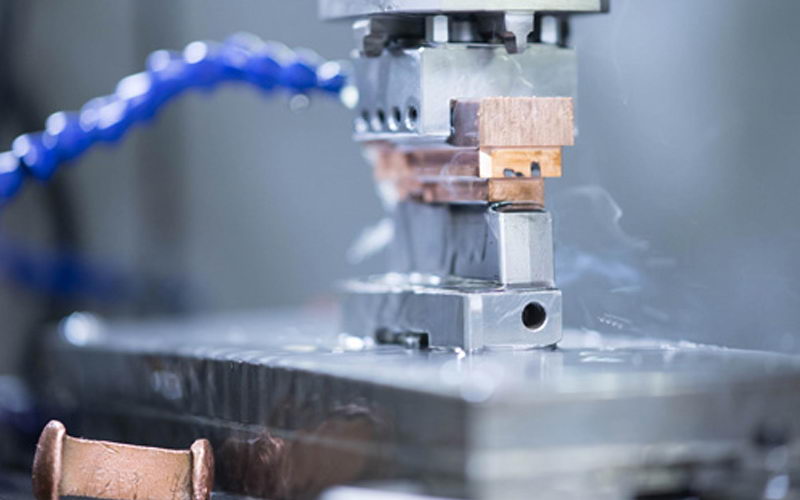

Kingyou has a experienced mold design team and complete mold production equipments, including milling machines, drilling machines, lathes, water mills, CNC manufacturing center, spark machines, wire cutters, etc. Relying on our strong precision mold design and manufacturing capabilities, and rich experienc of dealing with various manufacturing issues, we have been able to quickly make mould and produce plastic parts of the TWS earphones, wired Bluetooth earphones and f headphones, and cooperate with customers to releaes their products timely .

Our plastic parts manufacturing center has 10 advanced automatic injection molding machines, and the production capacity of plastic parts is more than 10 million per month . At present, all the plastic parts of TWS earphones, headphones and wired earphones can be independently produced and supplied by ourselves . We strictly control the quality and delivery time of plastic parts, constantly improve production efficiency and reduce production costs, and ensure that the finished earphones are delivered on time according to customer requirements.

With the concept of “high efficiency, high production capacity and FPY”, we continues to build our high-efficiency and integrated modern factory in high standards, constantly optimizes production process and improves production and management efficiency. At present, we have nearly 800 employees, 30 high-efficiency production lines, and monthly production capacity is more than 3 million pcs. We can realize the rapid production and delivery of TWS headphones, headphones, and wired headphones.

The company has a complete set of testing equipments on acoustics, circuit, mechanical and surface treatment, including anechoic room, audio precision, high and low temperature chamber, salt spray tester, etc., and has established a complete quality assurance system to realize the end-to-end whole process and system management control mechanism, from R & D design, supply chain, manufacturing delivery, after-sales service ets , to provides a strong guarantee for product quality.